|

|

|

| High Energy X-ray

Diffraction Microscopy (HEDM): Observing microstructure evolution inside of bulk materials

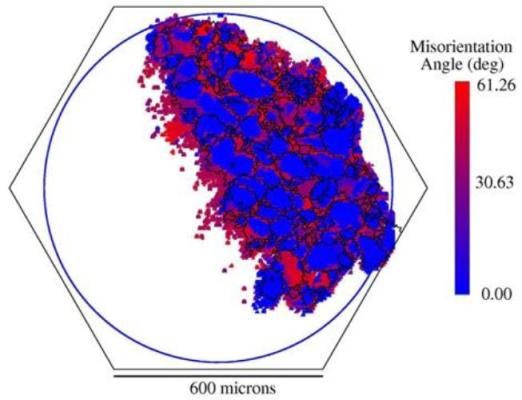

3D representation of local misorientations in a copper wire that has undergone light tensile strain (reference 3, below). |

||

Table

of Contents (modified November 2010)

Publications

Probing Microstructure Dynamics With X-ray

Diffraction Microscopy, R.M. Suter, C.M.

Hefferan, S.F. Li, D. Hennessy, C. Xiao, U. Lienert, B.

Tieman, J. Eng. Mater.

Technol., 130,

021007 (2008); proceedings of the Materials Processing

Defects-5 conference, Cornell University, July 2007).

3-Dimensional Characterization of Polycrystalline Bulk Materials Using High-Energy Synchrotron Radiation, U. Lienert, J. Almer, B. Jakobsen, W. Pantleon, H.F. Poulsen, D. Hennessy, C. Xiao, and R.M. Suter, Materials Science Forum 539-543, 2353-2358 (2007).

Tracking: a method for structural characterization of grains in powders or polycrystals, E.M. Laurdisen, S. Schmidt, R.M. Suter, and H.F. Poulsen, J. Appl. Cryst., 34, 744-750 (2001).

Three-dimensional maps of grain boundaries and the stress state of individual grains in polycrystals and powders, H.F. Poulsen, S.F. Nielsen, E.M. Lauridsen, S. Schmidt, R.M. Suter, U. Lienert, L. Margulies, T. Lorentzen, and D. Juul Jensen, J. Appl. Cryst., 34, 751-756 (2001).

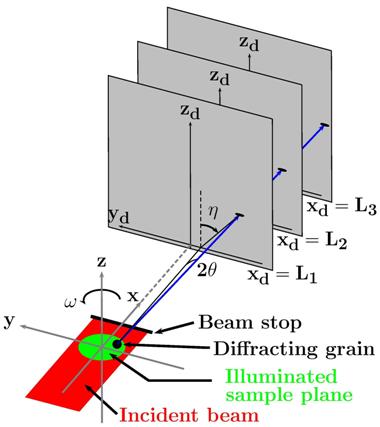

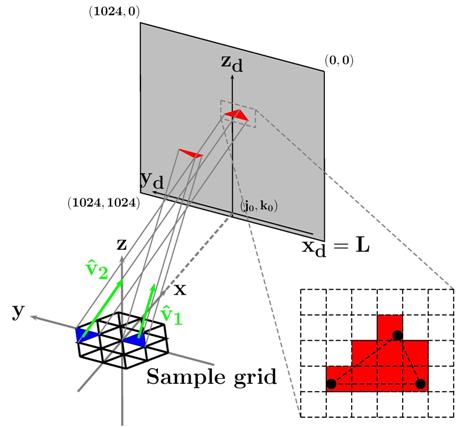

Schematic and Outline of the Technique

|

|

Apparatus at APS beamline 1-ID

|

Sample stage at 1-IDB.

|

|

The measurement crew (March 2010) at 1-ID command central |

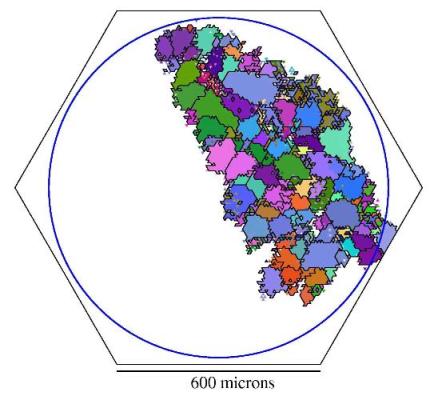

Some examples of

microstructure measurements using x-ray diffraction microscopy

(updates are coming soon...Nov 2010)

All data shown here

were collected at the Advanced Photon Source, beamline 1-ID

at Argonne National Laboratory. Participants include Chris

Hefferan, Frankie Li, Robert Suter (CMU) and Ulrich Lienert

(APS). Important computational assistance was provided by

Brian Tieman of the APS; analysis was performed using custom

software developed at CMU running on a 68 node cluster at

the APS.

Questions or

comments? e-mail:

suter@andrew.cmu.edu

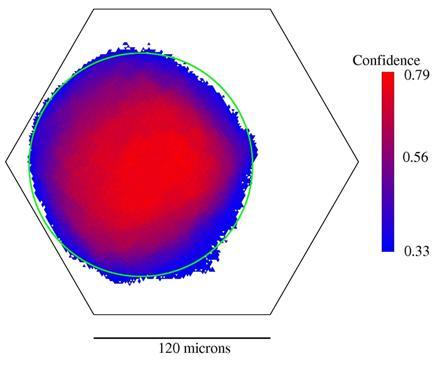

1. A section through the middle of a NIST certified

152 micron diameter single crystal ruby sphere. a) The

color map on the left shows misorientations from the average

orientation. Red-green-blue color contributions are

proportional to the Rodrigues vector describing the

misorientation. The maximum

rotation angle is 0.3 degrees. The

green circle shows the nominal 152 micron sample cross-section

while the hexagon shows the entire region included in the

analysis. The maximum radial deviations are roughly 8 microns.

b) The map on the right shows the 'confidence' fitting

parameter indicating maximal overlap of the simulation with

the experimental data in the central region and reduced

overlap near the edges. This reduction is due to background

subtraction removing weak edges of the imaged diffraction

spots. This fit is based on simulation of 1118 ruby Bragg

peaks about 115 of which could be observed at more than one

detector distance in the experimental data set. A confidence

of 0.79 means that over 90 simulated peaks overlap

experimentally observed peaks; 0.33 confidence implies 38

overlaps.

|

|

| Ruby sphere orientation map

(expanded scale) |

Relative confidence map for

image at left |

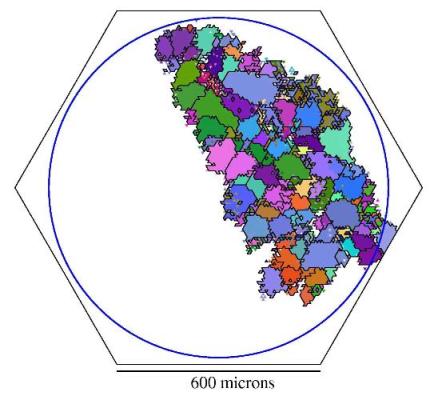

2. Near surface sections through an aluminum 1050 alloy

polycrystal sample. Colors indicate grain

orientations, again coded by Rodrigues vector components. The blue

circle indicates the 1 mm nominal sample diameter while the

hexagon is the analysis box. Black lines in the maps are draw

between elements with more than 5 degree misorientation.

| z = 0 |

|

| z = -10um |  |

| Point-to-point

crystallographic misorientation between the above two

layer measurements. Black lines show boundaries in the z

= 0 layer. |

|

Overview of relevance of HEDM microstructure

mapping techniuqe

Polycrystals are aggregates of single crystals joined together by a network of internal interfaces called grain boundaries. Polycrystalline materials, in both single and multi-phase forms, are ubiquitous in engineered systems: integrated circuits, aircraft and automotive components, communications devices, machine tools, and many others. The three dimensional geometry, arrangement, and relative orientation of the grains and the consequent grain boundary network (i.e., the microstructure) are crucial determinants of mechanical, chemical, thermal, and electrical properties. While there has been dramatic progress made in gaining three dimensional information about microstructure from two dimensional measurements made at surfaces (CMU MRSEC), it remains a great challenge to be able to watch microstructural evolution in response to external stimuli. With such observations made deep inside bulk materials, we should be able to deepen our understanding of phenomena and develop accurate constitutive relations governing the evolution and thereby learn how to do predictive calculations and to tailor microstructures to specific applications.

Three Dimensional X-ray Diffraction Microscopy (see articles listed above and the monograph by H.F. Poulsen, "Three Dimensional X-ray Diffraction Microscopy," Springer, 2004) is the only method available that can non-destructively image macroscopic volumes of internal microstructures. Based simply on Bragg diffraction, it is as versatile as, for example, electron backscatter diffraction analysis of surface microstructures. But by using high energy x-rays, it looks through millimeters of material without the need for destructive serial sectioning. Similar to serial sectioning work, measurements are done layer-by-layer. After the measurement, the sample still exists and can be re-measured after processing. Real-time dynamics can be monitored. The x-rays can penetrate sample chambers, making in-situ measurements possible. In sum, high energy x-ray diffraction microscopy (HEDM) promises to open the world of microstructure dynamics and response to a new light. In combination with powerful new computational tools, one can look forward to a new level of understanding and a new level of "dynamic three dimensional command over materials structure," (ONR BAA 04-024) processing, and properties.