|

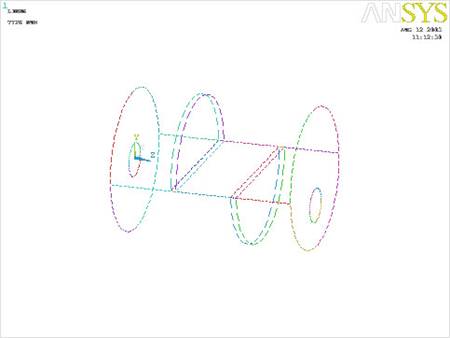

Now, we will create

the model. |

|

Click

Preprocessor>-Modeling->

and create a cylinder to define the basic shape of the muffler. |

|

NOTE:

It makes the creation of any 3 dimensional shape easier to go to the

ANSYS Main Menu (the top bar) and select

PlotCntrls>Pan Zoom Rotate and select the

Isometric view (ISO). This simply allows you a better view of the

volumes as you form them. |

|

Now, go to

Preprocessor>Modeling>Delete>Volumes Only

and click the cylinder just created. |

|

Click

Preprocessor>Modeling>Create>Areas>Rectangle>By 2 Corners

and create the area defining the inlet to the muffler. (A circle with

radius 0.03 m at the origin) |

|

Then

go to

Preprocessor>Modeling>Operate>Boolean>Overlap>Areas

and overlap the inlet to the corresponding face of the muffler. |

|

Now,

move the Workplane to the face of the muffler farthest from the

origin. Do this by selecting (on the top bar) Workplane>Offset WP

by Increments…. At this point, make sure the slider at the top

defining the number of snap increments it moves is set to 1 and

click the +Z button 3 times. This should

positiono the Workplane directly at the end of the muffler.

Click OK. |

|

Now

create the area defining the outlet for the muffler. The outlet is a

circle of radius 0.03 m offset 0.03 m in the –Y

direction. (These dimensions can be extracted from the AutoCAD

Drawing in the introduction) |

|

Again, Overlap the

area just created with its corresponding face. (the exit face of the

muffler) |

|

Now

create an “arbitrary” volume defined by all areas. |

|

This new volume is

the muffler, complete with inlet and outlet. |

|

Once the primary

muffler volume is finished, move the working plane 0.11 m (the

snap increment) along the Z axis such that it’s situated at the base

what will be the beginning of the impedance closest to the origin. |

|

Once the plane is

in place, create the volume to be subtracted from the muffler. (Use

Preprocessor>Modeling>Create>Volumes>Block>By 2 Corners and Z

) Since only

the top half of the muffler needs to be removed in this particular

slice set the height to a positive value and the width such that the

entire top hemisphere of the volume is included. These dimensions

were sufficient for the original model: |

The modeling of the

problem is done.

ELEMENT PROPERTIES

SELECTING ELEMENT

TYPE:

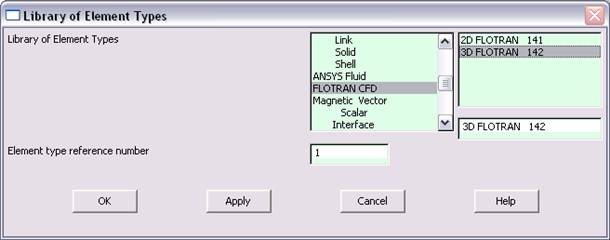

·

Click

Preprocessor>Element Type>Add/Edit/Delete...

In the 'Element Types' window that opens click on Add... The

following window opens:

·

Type

1 in the Element type reference number.

·

Click

on Flotran CFD and select

3D Flotran 142. Click OK. Close

the 'Element types' window.

·

So now

we have selected Element type 1 to be a Flotran

element. The component will now be modeled using the principles of fluid

dynamics. This finishes the selection of element type.

DEFINE THE FLUID

PROPERTIES:

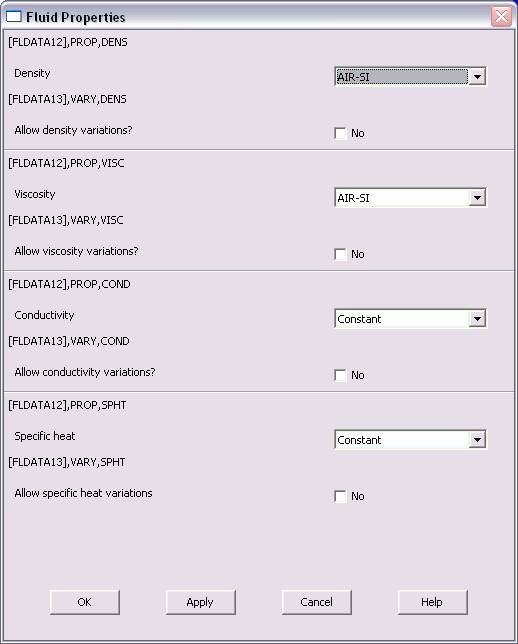

·

Go

to

Preprocessor>Flotran Set Up>Fluid

Properties.

·

On the

box, shown below, make sure the first two input fields read AIR-SI,

and then click on OK. Another box will appear. Click OK

to accept the default values.

·

Now

we’re ready to define the Material Properties

MATERIAL PROPERTIES

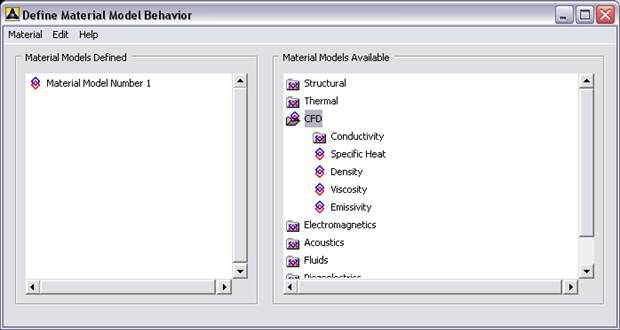

·

Go to

the ANSYS Main Menu

·

Click

Preprocessor>Material Props>Material Models.

The following window will appear

·

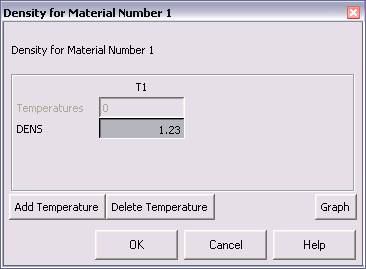

As

displayed, choose CFD>Density. The following window appears.

·

Fill in

1.23 to set the density of Air. Click OK.

·

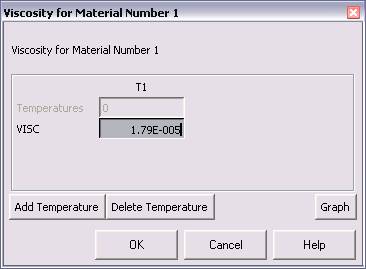

Now

choose CFD>Viscosity. The following window appears:

·

Fill in

1.79e-5 to set the viscosity of Air. Click OK

·

Now the

Material 1 has the properties defined in the above table so the Material

Models window may be closed.

MESHING:

DIVIDING THE CHANNEL

INTO ELEMENTS:

·

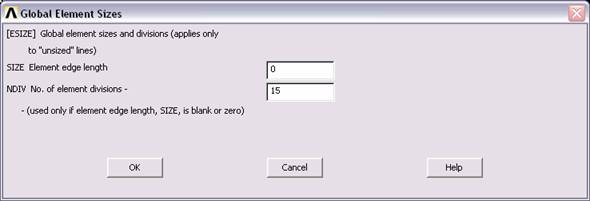

Go to

Preprocessor>Meshing>Size Cntrls>ManualSize>Global>Size.

·

In the

window that comes up type 15 in the field for 'No. of element

divisions'.

·

Now go

to

Preprocessor>Meshing>Mesh>Volumes>Free.

Click the muffler then Click OK. The mesh will look like the

following.

NOTE: The mountains

are meshed safely inside the block. Do not be alarmed that you can not

see them.

BOUNDARY CONDITIONS

AND CONSTRAINTS

·

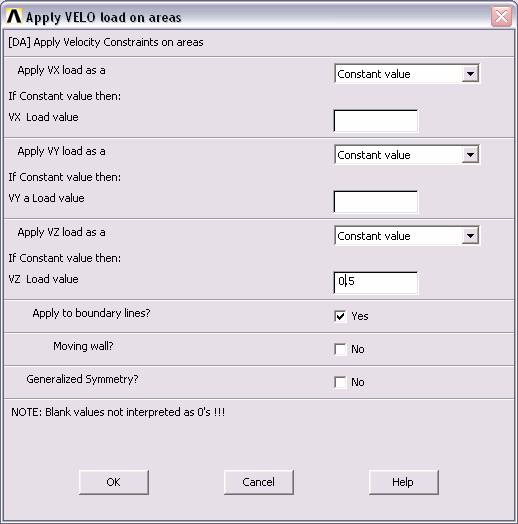

Go to

Preprocessor>Loads>Define Loads>Apply>Fluid CFD>Velocity>On Areas.

Pick the inlet of the muffler and Click OK. The following window

comes up.

·

Enter

0.5 in the VZ value field and click OK. The 0.5 corresponds to

the velocity of 0.5 meters per second of air flowing into the muffler.

·

Then,

set the Velocity to ZERO along all of the sides of the cylinder

forming the muffler. DO NOT FORGET the walls of the impedances

though, this is very important because indeed, no air flows along the

edges of those walls. This impeded flow is because of the “No Slip

Condition” acting on all theoretical walls. (VX=VY=0 for all sides)

·

Go to

Main

Menu>Preprocessor>Loads>Define Loads>Apply>Fluid CFD>Pressure DOF>On

Areas.

Pick the area defining the exit of the muffler and click OK.

·

Enter

0 as the pressure value. (This sets the pressure as atmospheric

allowing the air to pass over the car)

·

Once

all the Boundary Conditions have been applied, we can move on to solving

the problem.

SOLUTION

·

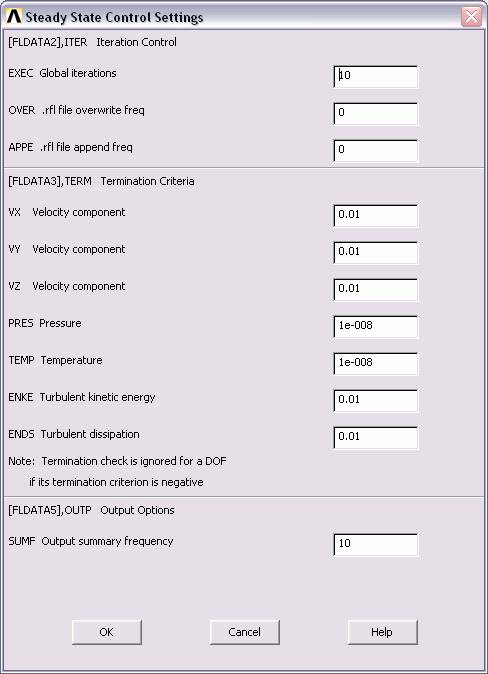

Go

to ANSYS

Main

Menu>Solution>Flotran Set Up>Execution Ctrl.

·

The following window appears. Change the first input field value to

10, as shown. No other changes are needed. Click OK.

·

Go

to

Solution>Run FLOTRAN.

·

Wait for ANSYS to solve the problem.

·

Click on OK and close the 'Information' window.

POST-PROCESSING

·

Plotting the velocity distribution…

·

Go

to

General

Postproc>Read

Results>Last Set.

·

Then, go to the ANSYS Main Menu (the Top Bar) and Click

Plot>Volumes.

·

After the volumes have been plotted, go to the

ANSYS

Main

Menu>WorkPlane

and select

Display Working Plane.

Now that the working plane is selected, go to

ANSYS

Main

Menu>WorkPlane >Offset WP by Increments

and rotate the working plane about the –Y axis such that it

bisects the cylinder along is longest axis.

(NOTE: you can make sure it is properly positioned by selecting

ANSYS

Main

Menu>PlotCntrls>Pan Zoom Rotate

and changing the views to verify).