Structural #5: Analysis

of a 3-D Beam structure

Introduction:

In this

example you will learn to use the 3-D Beam element in ANSYS.

Physical Problem: Structural

analysis of the bicycle frame made of hollow aluminum tubing shown in

the figure.

Problem Description:

|

The cycle frame is

made up of hollow aluminum tubing. These members can be modeled as 3D

Beams. 3D beams experience bending in two directions perpendicular to

the length of the beam. |

|

Units:

Use SI units only |

|

Geometry:

The tubing has an outer diameter of 25mm and a wall thickness of 2mm.

|

|

Material:

Assume the structure is made of aluminum with modulus of elasticity

E=75 GPa.

|

|

Boundary

conditions: The structure is constrained in the X, Y and Z

directions at the bottom three corners. |

|

Loading:

The cycle frame is subject to loading of 600N at the seat (point 2)

and to a loading of 200N at the pedal crank location (point 1).

|

|

Objective:

|

To determine

deflection at each joint. |

|

To determine the

maximum stress. |

|

Now assume that

your friend needs a ride home and she (he) sits on the back seat

(point 5). Determine the maximum stress now. Remember the extra

loading depends on the weight of your friend. :) |

|

|

You are required to

hand in print outs for the above. |

|

IMPORTANT NOTE:

You can use the stress list to determine the maximum stress but please

do not print this list. The easy way to determine the maximum stress

is to take guesses where the maximum stress should be, Zoom to those

points to get the node numbers or element numbers, then look for SMAX

values at those nodes/elements. |

|

Figure: |

STARTING ANSYS

|

Click on ANSYS

6.1 in the programs menu |

|

Select

Interactive. |

|

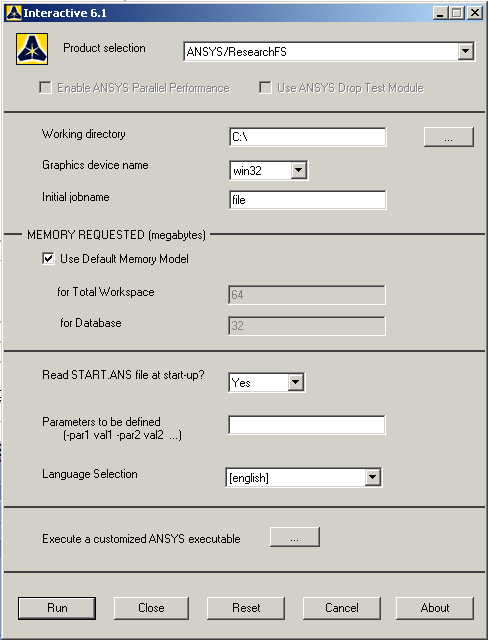

The following menu

that comes up. Enter the working directory. All your files will be

stored in this directory. Also enter 64 for Total Workspace and

32 for Database. |

|

Click on Run.

|

MODELING THE STRUCTURE

|

Go to

ANSYS Utility Menu. Click on

Workplane>Change

Active CS to..>Global Cartesian

|

|

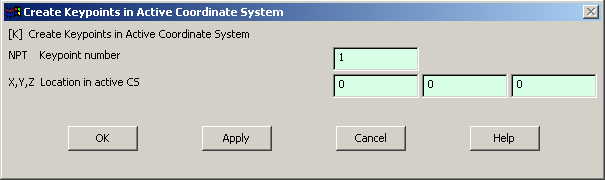

Go to

the ANSYS Main Menu

Preprocessor>Modeling>Create>Keypoints>In

active CS |

|

The following

window comes up: |

|

Fill in the

keypoint number (1,2,3...)

and the coordinates. Make sure you get the correct coordinates from

the figure. Create all the 8 keypoints.

Make sure the numbering of your keypoints

matches the numbering of the joints in the figure. |

|

If you cannot see

the complete figure then go to

Utility Menu>PlotCntrls>Pan Zoom Rotate

and zoom out to see the entire figure. |

|

Now create lines

connecting the keypoints |

|

Click

on

Preprocessor>Modeling>Create>Lines>Lines>In Active

Coord |

|

Create lines by

connecting keypoints. Click OK when all

of the lines are made |

|

You can use the

Utility Menu>PlotCtrls>Pan, Zoom, Rotate

window to rotate the model and see its 3D nature. |

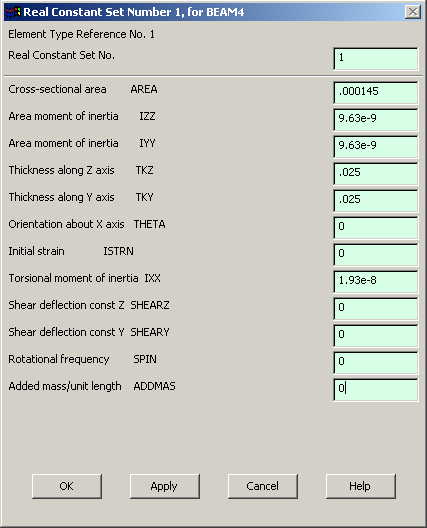

MATERIAL PROPERTIES

|

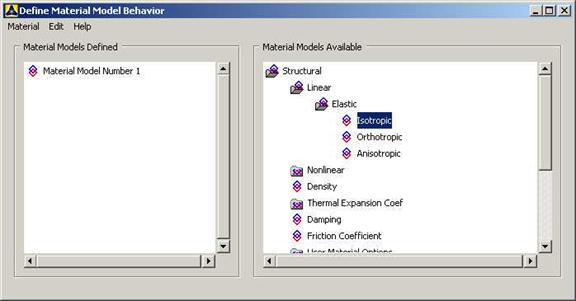

Go to the ANSYS

Main Menu |

|

Click

Preprocessor>Material Props>Material Models.

In the window that comes up, select

Structural>Linear>Elastic>Isotropic.

|

|

The following

window comes up for Material Model Number 1 |

|

Fill in 7.5e10

for the Young's modulus and 0.3 for minor Poisson's Ratio.

Click OK |

|

Now the material 1

has the properties defined in the above table. We will use this

material for the structure. |

ELEMENT PROPERTIES:

SELECTING ELEMENT TYPE

|

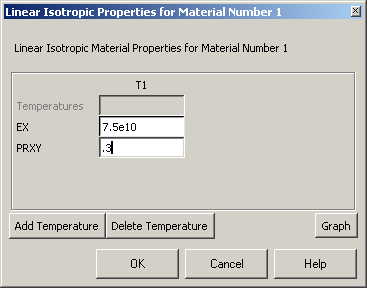

Click

Preprocessor>Element Type>Add/Edit/Delete...

In the 'Element Types' window that opens click on Add... The

following window opens. |

|

Type 1 in

the Element type reference number. |

|

Click on

Structural Beam and select 3D elastic. Click OK. Close the

'Element types' window |

|

So now we have

selected Element type 1 to be a structural Beam 3D elastic element.

The tubings will be modeled as elements of

type 1, i.e. structural 3D Beam element. This finishes the selection

of element type. |

|

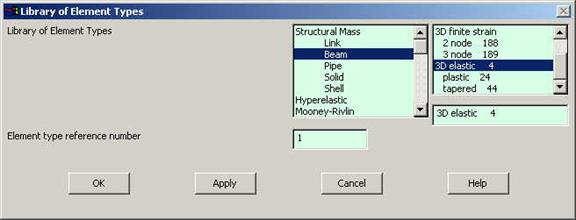

Now we need to

define the cross sectional area for this element. |

|

Go to

Preprocessor>Real Constants>Add/Edit/Delete… |

|

In the "Real

Constants" dialog box that comes up click on Add.

|

|

In the "Element

Type for Real Constants" that comes up click OK. The following window

comes up. |

|

Fill in the

relevant values and click on OK. |

|

We have now defined

the cross sectional area, area moment of inertia etc. of the 3D beam

element. |

MESHING:

|

DIVIDING THE FRAME

INTO ELEMENTS:

|

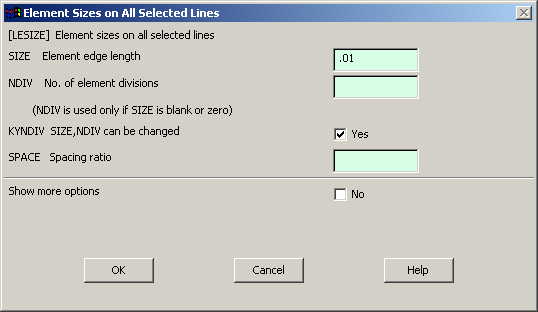

Go to

Preprocessor>Meshing>Size Controls>Manual Size>Lines>All Lines.

In the menu that comes up type 0.01 in the field for 'Element edge

length'. |

|

|

Now we have

defined each element to be of size 10 mm i.e. 0.01 meter |

|

Click on OK.

|

|

Now go to

Preprocessor>Meshing>Mesh>Lines.

|

|

Select all the

lines and click on OK in the "Mesh Lines" dialog box.

|

|

Now each line is

divided into 3D beam elements. |

|

BOUNDARY CONDITIONS AND

CONSTRAINTS:

|

APPLYING BOUNDARY

CONDITIONS

|

The cycle is

constrained in all DOFs at the point 3,4,6,7,8.

|

|

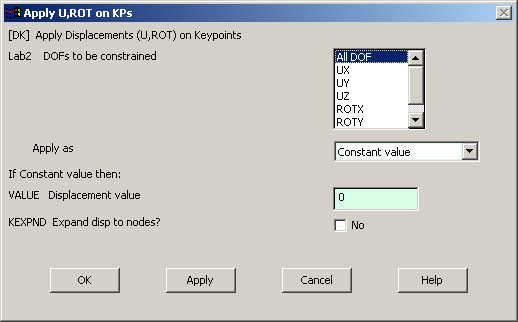

Go

to Main Menu.

Preprocessor>Loads>Define Loads>Apply>Structural>Displacement>On

Keypoints. |

|

Select each

keypoint on which you want to apply

displacement constraints. The following window comes up. |

|

|

Select All DOF

and click OK. |

|

APPLYING FORCES

|

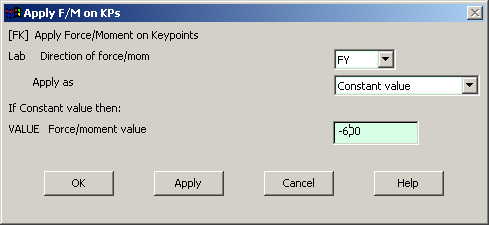

Go to Main Menu

Preprocessor>Loads>Define Loads>Apply>Structural>Forces/Moment>On

Keypoints.

|

|

Select the

keypoint where the force acts. Here we

use keypoints because there are a lot of

nodes and therefore, it is easier to pick

keypoints. |

|

Click on OK in

the "Apply F/M on Keypoints" window. The

following window will appear: |

|

Enter the value

of the force in the Y direction. |

|

Repeat the

procedure to apply the force on the other

keypoint. |

|

|

The model should

look like the one below: |

|

Now the Modeling of

the problem is done. |

SOLUTION:

|

Go to ANSYS

Main Menu>Solution>Analysis Type>New Analysis.

|

|

Select static and

click on OK. |

|

Go to

Solution>Solve>Current LS.

|

|

Wait for ANSYS to

solve the problem. |

|

Click on OK and

close the 'Information' window. |

POST-PROCESSING:

|

Listing the

results: |

|

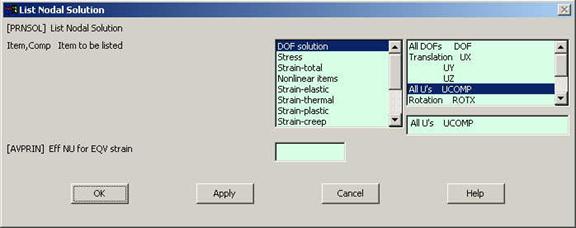

Go to ANSYS Main

Menu

General Postprocessing>List Results>Nodal

Solution.

The following window will come up. |

|

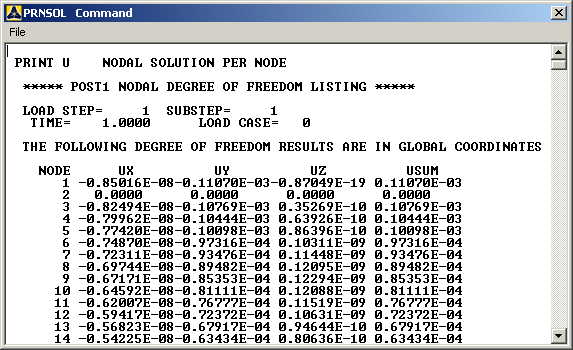

Select DOF

solution and All U's. Click on OK. The nodal displacements

will be listed as follows. Note that the node number may not be the

same node on your project depending on the order in which you picked

your lines to be made. |

|

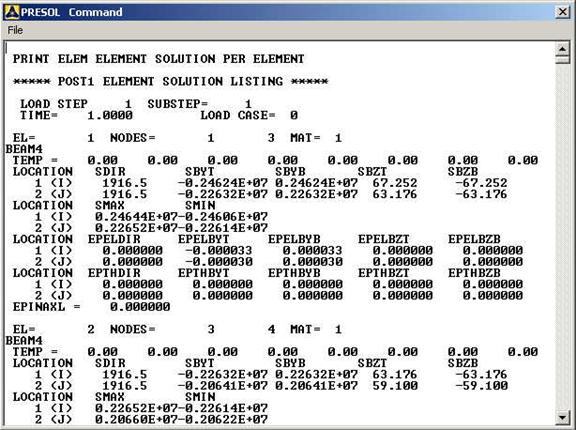

Similarly you can

list the stresses for each element by clicking

General Postprocessing>List

Results>Element Solution.

Now select LineElem Results.

The following table will be listed. |

|

IMPORTANT NOTE:

You can use this list to determine the maximum stress but please do

not print this list. The easy way to determine the maximum stress is

to take guesses where the maximum stress should be, Zoom to those

points to get the node numbers or element numbers, then look for

SMAX values at those nodes/elements. |

MODIFICATIONS:

|

You can also plot

the displacements and stress. |

|

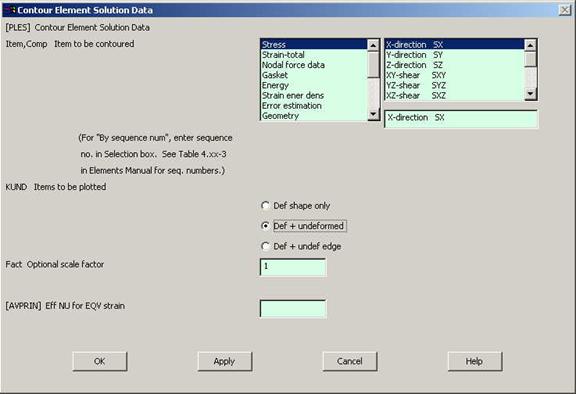

Go to

General Postprocessing>Plot

Results>Contour Plot>Element Solution.

The following window will come up. |

|

Select a stress to

be plotted and click OK. The output will be like this.

|

|