Thermal 5: 3D Heat

Conduction within a Solid

Introduction:

In this example you

will learn to build and assess #3D geometries in heat transfer by

modeling an object subjected to requirements and specific boundary

conditions. Using ANSYS will allow you to output the temperature

distribution in an extremely simple and accurate way.

Problem Description:

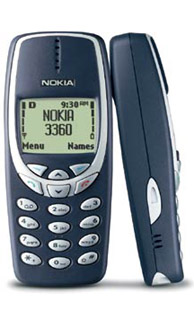

·

We

assume that our phone is a rectangular solid, with filleted corners as

they appear in the image.

·

All

units are S.I.

·

Boundary Conditions:

2) All faces except that of the battery have convective boundary

layers.

3) The battery generates heat at a rate of 50 W/m^2/s.

5)

Heat is uniformly generated in the bock at a rate of 20 W/m^2.

·

Material Properties: (Steel)

h =

50 W/(m^2*K)

k(innards)

= 10 W/m-K

k(lithium) = 84.8 W/m-K

k(plastic) = 0.18 W/m-K

·

Objective:

To determine the nodal temperature

distribution and create contour plot.

·

Dimensions

1.

Cellphone: 0.1143m

long x 0.0254m thick x 0.0508m wide

(4.5 inch x 1 inch x 2 inch )

2.

Battery:

Length: 50.8

millimeters Thickness: 10.16 millimeters Width 38.1

millimeters (2 inch x 0.4 inch x 1.5 inch)

Note that the actual

dimensions of the battery are: Length: 53 millimeters Width 37

millimeters Thickness: 10 millimeters (2.087 inch x 1.457

inch x 0.3937 )

We will use

approximations because the heat transfer will still display the same

general distribution

Note: For any

necessary conversions, this site is useful:

http://www.convert-me.com/en/convert/length

The dimensions of the

drawing are in English because the specs of the phone given on the web

are in English (making the CAD drawing easier to build in English)

REMEMBER TO CODE

ANSYS WITH SI, not English

Note: .1 inch =

2.54 mm

Also, R0.50in =

0.0127m

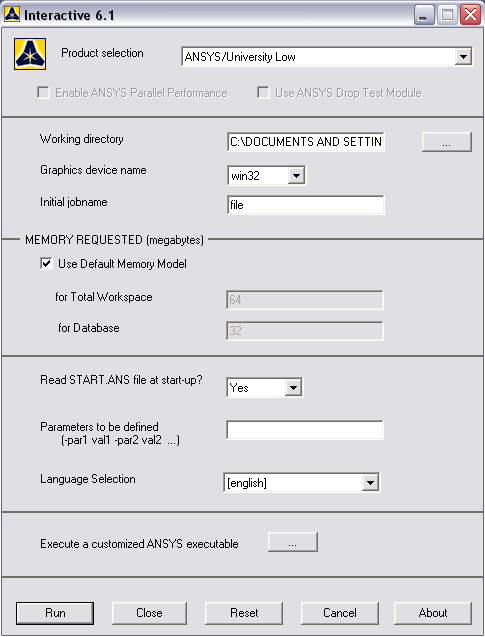

Starting ANSYS:

·

Click

on

ANSYS

6.1

in the

programs menu.

·

Select

Interactive.

·

The

following menu comes up. Enter the working directory. All your files

will be stored in this directory. Also under

Use

Default Memory Model

make

sure the values

64

for Total Workspace, and

32

for Database are entered. To change these values unclick

Use

Default Memory Model.

·

Click

RUN

Modeling the

Structure:

·

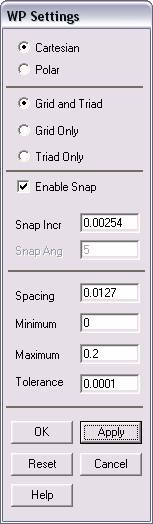

Go to

the ANSYS Utility Menu (the top bar)

·

Click

Workplane>WP Settings…

·

The

following widow comes up:

·

Check

the Cartesian and

Grid and Triad Only buttons

·

The

first step is to create the inner volume to represent the space in the

phone that is occupied by the microchips and transistors.

·

Enter

the values shown in the figure above and then click OK. Note that

we are using a spacing increment of .1 inches or 2.54 millimeters. This

will help in a modeling step.

·

Go to

the ANSYS Main Menu (on the left hand side of the screen) and click

Preprocessor>Modeling>Create>Volumes>Blocks>By 2 Corners and Z

·

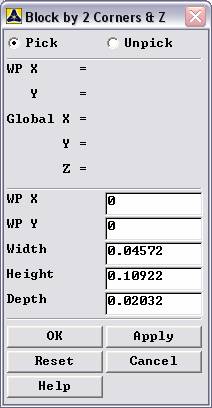

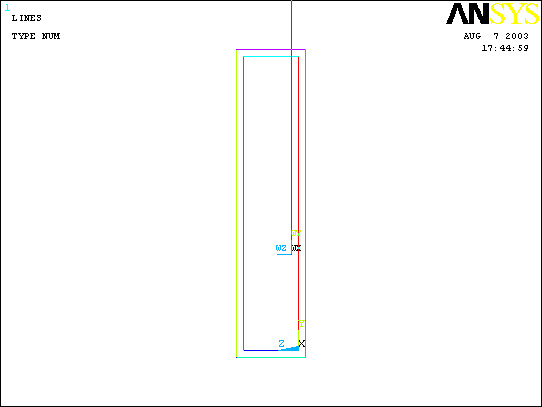

The

following window comes up:

·

Enter

the values as shown and click OK.

·

Now

change the view to isometric mode, using

Menu>Plot Controls>Pan Zoom Rotate and by clicking the ISO

button. The plot should have zoomed to the new part.

·

Now you

have created the external phone. If at any time you cannot see the

complete Workplace then go to Utility

Menu>Plot Controls>Pan Zoom Rotate and zoom out to see the

entire Workplace. If you want to see the grid itself, go to

Utility Menu>Workplane>Display Working Plane

·

The

next step is to create the outer volume.

·

Go to

Utility Menu>Workplane>Offset WP by

increments and click these buttons to offset the workplane by

-.1 inches in each direction. This will enable you to create the inner

volume easily.

·

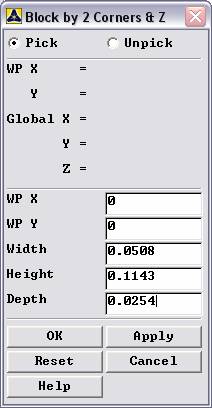

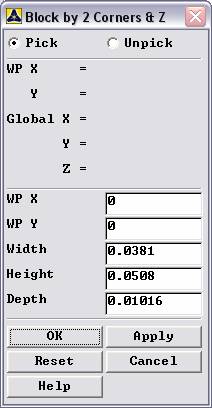

Next

use

Preprocessor>Modeling>Create>Volumes>Blocks>By 2 Corners and Z

again and this time enter the following:

Note that these

dimensions are simply the previous ones, minus 0.00508 which is .1x2

inches.

·

If you

messed something up, remember not to select Pick All when

deleting anything now, since you don’t want to destroy the model of the

inner volume.

·

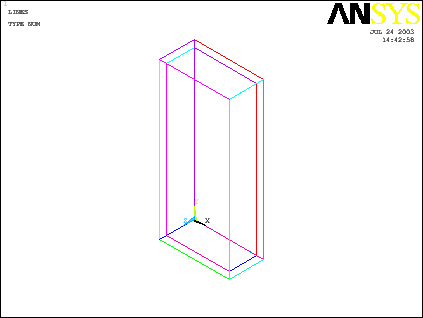

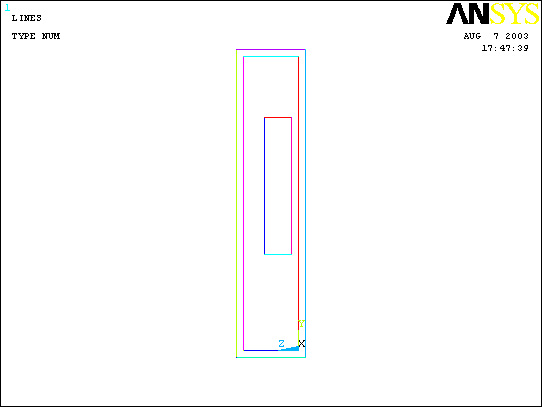

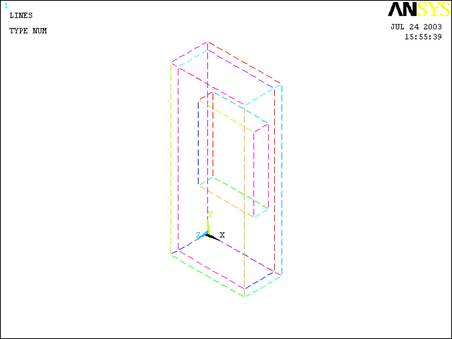

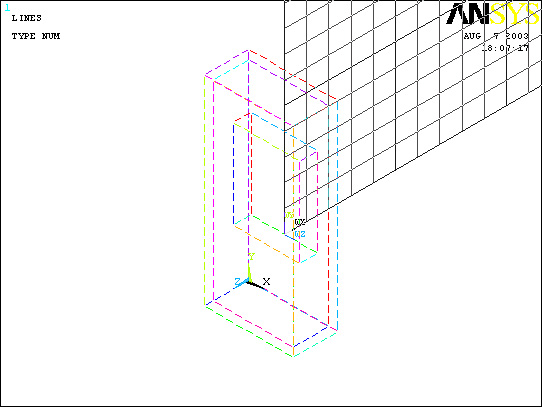

The

model should look like this now if you plot lines (Utility

Menu>Plot>Lines)and dynamically rotate the solid(Utility

Menu>PlotCntrls>Pan Zoom Rotate): (note, you have a black

background)

·

The

next series of steps involves creating the volume for the battery.

·

First,

use Offset WP by increments and increment the Workplane by two

positive increments in the Z direction. Next, change the snap

and grid increments of the workplane settings to 0.0381 m (1.5

inches, the distance between the bottom of the phone and the beginning

of the battery). Use Offset WP and offset in the Y direction by

one positive increment. Next, change the increments once

more to 0.00635 m (0.25 inches). Displace the WP in the X

direction one positive increment.

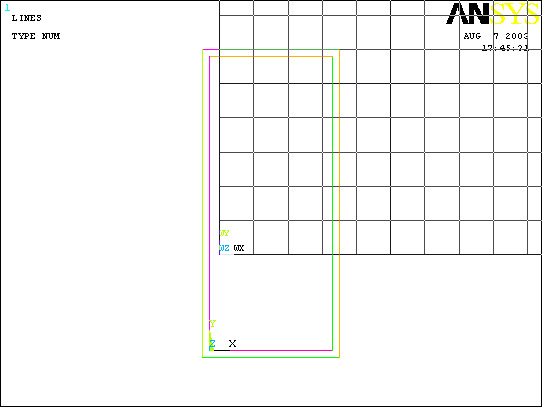

·

The

workplane will appear here: Note that The Pan Zoom Rotate settings here

are “Front” instead of ISO and only the lines are plotted: Basically,

the image should look like the CAD drawing from the top of the tutorial,

and the bottom corner is where the battery will be referenced from.

·

Now

create the volume for the battery:

·

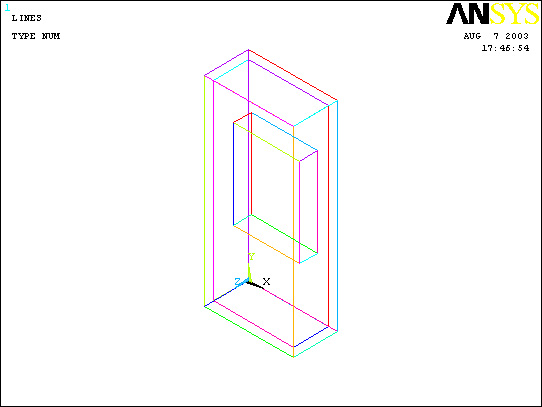

The

completed model will look like this: (note that I did not replot the

volumes because we wouldn’t be able to see any of the inner volumes!

And in ISO mode

·

One

final step that needs to be executed involves explaining that the

volumes overlap each other, so that when meshing, the volumes are

separate from each other. This is accomplished by choosing

Preprocessor>Modeling>Operate>Overlap>Volumes

·

First

select the outside layer and the inside layer (not the battery!) and hit

Apply. Then select the inside volume and the battery and hit OK. This

should resolve all the volumes. You can test this but plotting lines and

then trying the step again, the volumes should each be selected

separately… if so, then hit cancel and move forward.

Material Properties:

·

Now

that we have built the model, material properties need to be defined

such that ANSYS understands how heat travels through this composite

solid.

·

Go to

the ANSYS Main Menu

·

Click

Preprocessor>Material Props>Material Models.

·

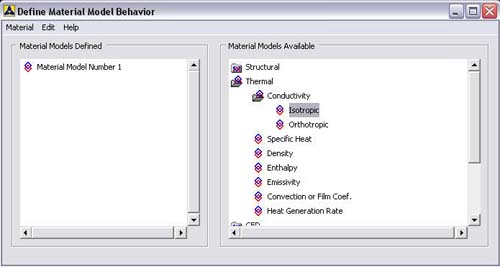

The

pop-up window will now look like this:

·

In the

window that comes up choose

Thermal>Conductivity>Isotropic.

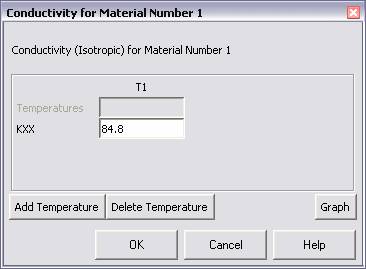

(Double click Isotropic). The following window comes up:

·

Fill in

84.8 for Thermal conductivity. This defines the conductivity of

Lithium and correlates material 1 with it. Click

OK.

·

Choose

Define

Material Model Behavior>Material>New Model

and define another conductivity for the new model, that of the

innards (10 W/m K) and then repeat to define the Plastic case of the

phone (0.18 W/m K)

·

Now

exit the “Define Material Model Behavior” Window

Element Properties:

·

Now

that we’ve defined what material ANSYS will be analyzing, we have

to define how ANSYS should analyze our block.

·

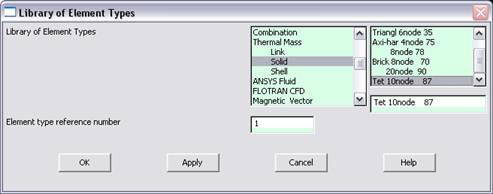

Click

Preprocessor>Element Type>Add/Edit/Delete...

In the 'Element Types' window that opens click on Add...

The following window opens:

·

Type

1 in the Element Type reference number.

·

Click

on Thermal Mass Solid and select Tet 10node 87. Click

OK.

Close the 'Element types' window.

·

Now we

have selected Element Type 1 to be a Thermal Solid 10node

Element. This finishes the section defining how the part is to be

analyzed.

Meshing:

·

This

section is responsible for telling ANSYS how to divide the block such

that it has enough nodes, or points, to analyze to make an accurate

enough analysis.

·

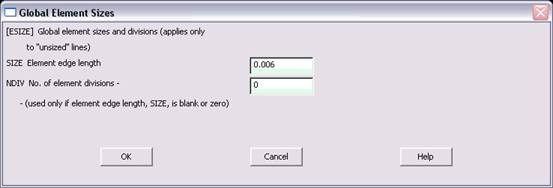

Go to

Preprocessor>Meshing>Size Controls>Manual Size>Global>Size.

In the menu that comes up type 0.006 in the field for ”Element

edge length”.

·

Click

on

OK.

Now when you mesh the figure ANSYS will automatically create square

meshes that have an edge length of 0.006m along the lines you

selected.

·

Now go

to

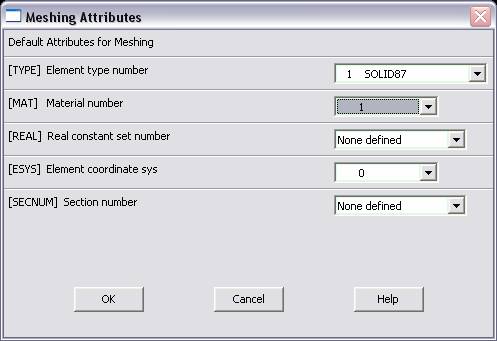

Preprocessor>Meshing>Mesh Attributes>Default Attributes.

The window is shown below:

·

Here

you finally put together material model and material type. Select the

appropriate material to mesh (first 1, lithium, as defined in the

Material Properties section) and pick what element type to use (selected

by the Element Type Number). Once this has been verified,

Click OK and proceed to

Preprocessor>Meshing>Mesh>Volumes>Free

·

A popup

window will appear on the left hand side of the screen. This window

allows you to select the area to be meshed.

·

Click

anywhere within the lithium battery you created to select the volume and

then click

OK

in the pop-up window.

·

Return

to Default Attributes and this time, select Material Number 2, to

model the innards of the phone.

·

Finally, choose material 3 and mesh the plastic casing.

·

The

model should now look like this:

ISO

ELEMENTS

ISO

LINES

Boundary Conditions

and Constraints:

·

Now

that we have modeled the phone and defined how ANSYS is to analyze it we

will apply the appropriate Boundary Conditions.

·

Go to

Preprocessor>Loads>Define Loads>Apply>Thermal

(from here one can apply any of the loads, or Boundary Conditions,

offered by ANSYS.)

Apply

Convection (Case)

·

First

we’ll apply the Convection Boundary layer around the model. For this

click Convection>On Areas within

the Thermal Load category.

·

A

dialog window will appear on the left hand side of the screen. This

window allows you to select the areas you wish the load to be applied.

·

Select

the outside areas of the phone and click OK.

The following window will appear:

·

Fill in

the h value in the Film Coefficient blank and the Air

temperature in the Bulk Temperature blank. Click

OK when finished.

Apply Heat Generation

·

The

next step is to add the constraint of heat generation.

·

Preprocessor>Loads>Define Loads>Apply>Thermal>Heat Generat>On Areas.

(Heat Generat is just short for Heat Generation). You select Areas

again because you have to apply this condition uniformly across the

block.

·

Click

anywhere within the area to select it and then click

OK.

·

The

voltage of the battery is rated as 3.7V and the internal resistance is

on the order of 200 milli ohm. Therefore, the total power is I2R

= 2.738 W which break down to (V = 0.0000196644768 m3) =

139235.843 W/m3

·

Enter

139235.843 W/m3 as the heat generation value in

the pop-up window that appears:

·

Now we

have applied all the necessary boundary conditions so we move on to the

Solution.

Solution:

·

Go to

ANSYS

Main

Menu>Solution>Analysis Type>New Analysis.

·

Select

Steady

State

and click on

OK.

·

Go to

Solution>Solve>Current LS.

·

An

error window may appear. Click

OK

on that window and ignore it.

·

Wait

for ANSYS to solve the problem.

·

Click

on

OK

and close the 'Information' window.

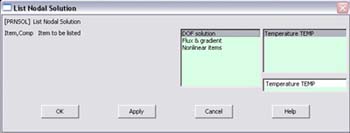

Post-Processing:

·

This

section is designed so that one can list the results of their analysis

as a nodal solution

·

Go to

the ANSYS Main Menu. Click

General

Postprocessing>List Results>Nodal Solution.

The following window will come up:

·

Select

DOF

solution

and

Temperature.

Click on

OK.

The nodal temperatures will be listed as follows:

·

Within

this window one can numerically find the maximum and minimum value of

the temperature within the block.

Modification /

Plotting the Results:

The last section

displayed the numerical results, but most analyses will require a plot

of the temperatures on the block in addition to the numerical results.

This is how you go about doing that…

·

First

go to

Utility Menu>PlotCtrls>Style>Hidden Line Options

·

The

following window appears. Choose Q Slice Z Buffer and Working

plane as shown below

|

Now there will be a

cross section shown of the temperature distribution in the direction

of the workplane. Try rotating the workplane so that this slice is

shown (you may want to replot lines): |

|

To see the

workplane, return to

Utility Menu>Workplane>WP Settings…

and choose Grid and Triad |

|

Then use

Workplane>Offset WP by increments

and use offset by angles (change increments to 90 degrees) Offset in

the +Y direction 90 degrees, then by 3 snap increments in the +Z

direction. Should look something like this: |

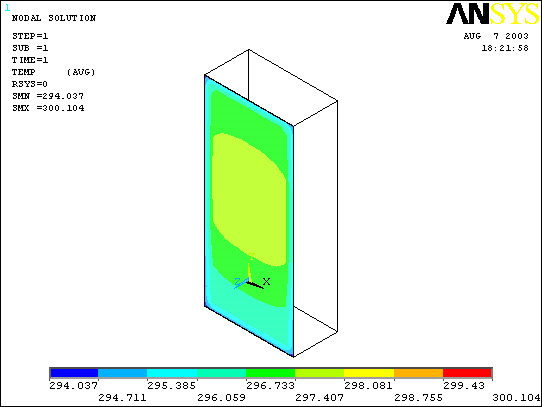

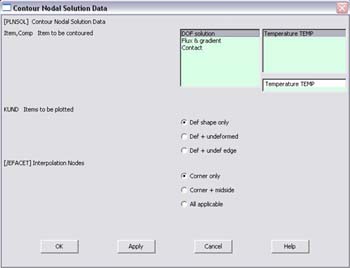

Choose

General

Postprocessing>Plot Results>Contour Plot>Nodal Solution.

The following window will come up:

|

Check the entries

and hit OK. The result should be something like below! |

ISO

ISO

zoomed in on bottom

Now offset the WP

back to the original angle (rotate in the –Y direction by 90 degrees)

and then choose Utility Menu>Workplane>Offset

WP to>Global Origin. Change the WP settings to 0.02261 and

offset the WP once more by 1 snap increment in the +Z direction. If you

replot the contour, you can see that the temperature of the phone near

the ear will be on the order of 296 K which is 73.13 degrees Fahrenheit.

Some people might find that uncomfortable. This of course, is a crude

model of the phone as most of us with phones have experienced more

discomfort. Note that the phone is also warmer in the middle area,

directly across from the battery…which is sensible and also more likely

to be noticed in general.