|

Check

your connections. It is particularly important that the power be applied

to the op-amp in the right direction, and that none of the pins on the

chip are shorted to each other. Be careful that none of the resistor

or capacitor leads touch each other. |

|

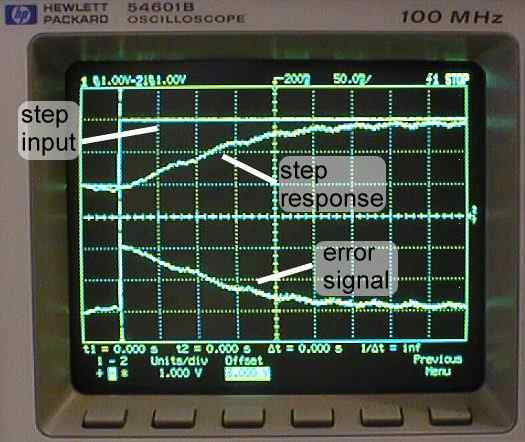

Set

the function generator to a square input of amplitude 1V, offset 1V,

and frequency 1Hz. This will be a square wave alternating between 1V

and 3V. |

|

Set

the trigger to source 1 at a level of 2V with upward slope. |

|

Set

both voltage scales on the oscilloscope to 1V/div. |

|

Set

the time scale to 50ms/div, and the time delay to 200ms. |

|

Adjust

the vertical position of traces 1 and 2 so that the origin of each is

at the origin of the screen. |

|

Set

trace 2 to invert mode. This will get rid of the negative sign

when viewing the signal. |

|

Turn

on the power. If the voltage levels on the power supply do not go up

to 20V, then turn it off immediately since something is most

likely shorted. If this is the case check your connections. |

|

If

the motor spins uncontrollably, you are in positive feedback. If this

is the case, interchange the two leads from the tachometer. |

|

Measure

the error by using the math function on the oscilloscope. To do this,

press the +/- button, turn the math function on, select menu, and choose

the ``-'' function. Set units/div=1V and offset=3V using the knob normally

used for cursors. |

|

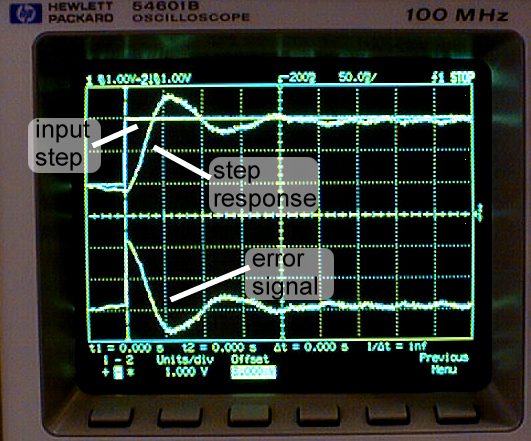

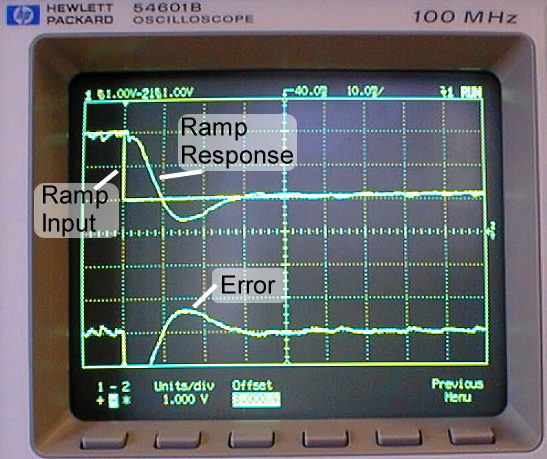

Use

the cursors to measure the following:

|

Steady

State Error |

|

Peak

Time, Tp. |

|

98%

Settling Time, Ts. |

|

%

Overshoot, %OV. |

|

|

Print

this screen. |